Design features of hollow shaft stepper motors from Vicent's blog

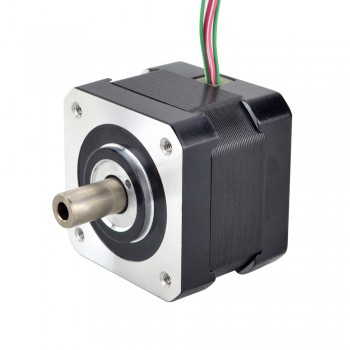

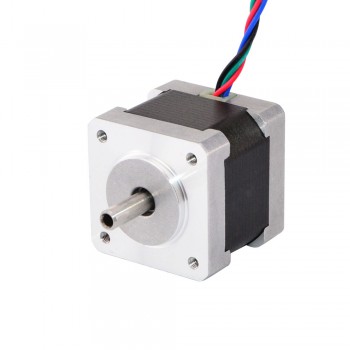

1.What is a hollow shaft stepper motor?

The hollow shaft stepper motor is a special kind of stepper motor. Its internal structure adopts a hollow design and is mainly composed of magnets, inner and outer frames, bearings, coils and other parts. This kind of motor has the advantages of high power density, small size, high efficiency, low noise, low temperature rise and high reliability, so it has important applications in aerospace, military, automobile, medical, robotics and other fields. . The design of the hollow shaft stepper motor greatly optimizes the mechanical design, facilitates wiring, and saves design space and production costs.

2.How to reduce the temperature of hollow shaft stepper motor

1.Fan cooling method: Install a fan on the stepper motor, and use the fan to circulate the air around the motor to accelerate the dissipation of heat to achieve the purpose of heat dissipation. This method is simple and effective, and can significantly reduce the temperature of the motor.

2.Heat sink cooling method: Install a heat sink on the surface of the stepper motor, and transfer the heat inside the motor to the outside through the heat sink to accelerate the dissipation of heat, thereby achieving the purpose of heat dissipation. The heat sink can effectively conduct heat from the inside of the motor to the outside, helping the motor to cool down.

3.Liquid cooling method: Set up a liquid cooling system inside the stepper motor to transfer the heat inside the motor to the outside through the liquid to accelerate the dissipation of heat to achieve the purpose of heat dissipation. The liquid cooling system can absorb and dissipate the heat generated by the generator more effectively, and is suitable for application scenarios with high temperature control requirements.

4.Reducing current method: By reducing the driving current of the stepper motor, the heat generated by the motor is reduced to achieve the purpose of heat dissipation. Reducing the current can reduce the loss and heat of the motor, thereby lowering the motor temperature.

3.Application areas of hollow shaft stepper motors

1.In the field of automation equipment, hollow shaft stepper motors are widely used in robots, automated production lines, CNC machine tools, etc. to provide precise position control and motion control while facilitating the passage of cables, air pipes, etc.

2.In terms of medical equipment, hollow shaft stepper motors are often used in surgical robots, medical imaging equipment, laboratory automation equipment, etc., to meet the requirements of high precision and reliability, and to facilitate the layout of cables, trachea, etc.

3.In printing equipment, hollow shaft stepper motors are used to drive printing rollers, paper conveying and other components to improve the integration and reliability of the equipment.

4.In the field of textile machinery, hollow shaft stepper motors are used to drive components such as yarn winding and looms, and also improve the integration and reliability of the equipment.

5.In terms of stage equipment, hollow shaft stepper motors are used to drive stage lifting, rotation and other components to improve the integration and reliability of the equipment.

6.In the field of aerospace, hollow shaft stepper motors are used to drive components such as rudder surfaces and landing gear to facilitate the passage of cables, air pipes, etc., and improve the integration and reliability of equipment.

7.In vehicle engineering, hollow shaft stepper motors are used to drive power windows, seat adjustments and other components to facilitate the passage of cables, air pipes, etc., and improve the integration and reliability of equipment.

4.Design features of hollow shaft stepper motors

1.Energy-saving characteristics: The energy conversion efficiency of hollow shaft motors is very high. The maximum efficiency is generally above 70%, and some products can reach above 90%. Compared with iron core motors, they have higher energy utilization.

2.Control characteristics: rapid starting and braking, extremely fast response, the mechanical time constant is less than 28 milliseconds, and some products can reach within 10 milliseconds, which makes it easy to adjust the speed under high-speed operation within the recommended operating area. Sensitive adjustment.

3.Drag characteristics: The operation stability is very reliable, and the fluctuation of the rotation speed is very small. As a micro motor, the fluctuation of the rotation speed can be easily controlled within 2%, ensuring the smooth operation.

4.High power density: Due to its compact structure, the hollow stepper motor is smaller in size, which can save space and thus improve energy utilization.

5.High efficiency: The hollow design can reduce the weight of the motor and increase the space of the magnetic circuit, thereby increasing the power density of the motor.

6.Low noise: The noise of the hollow stepper motor is much smaller than that of the traditional stepper motor, which can better protect the environment.

7.Low temperature rise: The temperature rise of the hollow stepper motor is lower than that of the traditional stepper motor, which can better ensure the service life of the motor and better meet the needs of users.

8.High reliability: The reliability and stability of hollow stepper motors are much higher than traditional stepper motors, and they are suitable for applications that require high reliability and stability.

9.Hollow structure: The center of the motor shaft has a hollow hole, allowing materials, signals, light, etc. to be transmitted through the axial space. This design can achieve a more compact and optimized layout in machine design.

The Wall