fannyzeng's blog

Compared with traditional printing, the printing process of digital printing is more simple. While it doesn't completely drop the need for traditional printing. Digital printing offers a more green and cost-effective printing method to book printing companies in China . Compared with other printing methods, digital printing is more "green". To achieve green environmental protection, digital printing is the best choice.

Computers and digital printing have made the printing industry greener than ever before. The benefits of applying digital processing are evident in the various printing processes. Where chemicals are often used. We can see the fact that digital printing has a great influence on prepress and other fields. The United States recently published "Print News" weekly. Who published "Digital Printing: Make printing greener".

Why say digital printing makes printing greener?

Why say digital printing makes printing greener?

Check out the below to find the answer

1. Digital printers can cut air pollutant emissions

What is the biggest impact of printing on the environment? After any material passes through a printing press or prepress operating system. It becomes either a product or a waste product. That is to say, every piece of raw material we use to produce prints is to some extent a waste maker.

Air pollution from the use of ink solvents, coating fluids, and dampening solutions. Cleaning solutions, along with hazardous waste from these inks and solvents. Press cleaner residues and film cleaning, plate making, and cleaning systems generate wastewater. All these waste streams can cause great harm and damage to human health. And the ecological environment inside and outside the factory.

But, with the use of digital prepress technology and printing presses. Many harmful substances can be avoided or produced in very small amounts.

First of all, we can see the environmental protection potential of digital printing from billboard printing. And staples poster printing market.

Screen printing machines occupy a big market position in billboards and poster printing. Which need the application of solvent or water-based inks, UV-curable inks and coatings. Yet, the pollution problem does not occur in product printing. But in the screen cleaning process after a job is completed or after a working cycle.

Screen printing equipment is generally cleaned with solvents in cleaning potions. Often, it is necessary to use a strong concentration of solvent to dissolve the dry ink. Which is very harmful to the body. The solvent gas in the cleaning area and the printing workshop needs an exhaust system to discharge these harmful gases. So handling the cleaning solvent of the harmful waste must obey the relevant government regulations. Thus, small screen printing machines have a lot of hazardous waste disposal problems.

With the advent of giant-format digital press. Which solves the problem of printing widths from 30 inches to 17 feet. Inkjet presses are now very capable of printing posters and billboards. While also minimizing air pollutant emissions. In fact, in some states of the US have excluded digital printing from the provisions of clean air laws. UV-curable inkjet printers make a great contribution. To reduce the impact of printers on physical health and the external environment. So when evaluating the benefits of purchasing a digital printing or prepress system. Remember to factor environmental costs and health needs into your ROI.

2. Digital technology can reduce the cost of industrial waste disposal

Cheap label printing is another beneficiary of digital printing.

Gravure technology and flexo printing technology of narrow web rotary printing need liquid ink. The solvent or water in it contains many chemical additives. Such as glycols, and some printing machines use UV curing ink. But the final procedure of each job must clean the inkjet table. And transfer the cylinder with a print cleaning solvent. Here we also have to face the problem of air pollution emissions and hazardous waste removal. Digital printing presses no longer need solvents or other cleaning solutions. Such as water-based inks to clean the printing press. So the result is a significant reduction in exhaust and waste emissions.

Lithographic printing machines, especially those with smaller print runs. Which have applied digital printing to drop dampening liquids. Blanket cleaning cloths and a considerable part of startup waste. Digital printing eliminates the printing plate preparation. Thereby making exposure and the generation of waste in the prepress system reduced. Needless to say, digital processing effectively mitigates the environmental damage of printing.

3. Digital printing does not need making printing plates.

Digital prepress has also revolutionized workflows. Darkroom chemicals were once a deadly hazard in wastewater. Because of the amount of silver in the film and the nature of the developing chemicals. But that's gone forever. With computers to plates, traditional printing does not need to use film as a medium to make printing plates. And with direct printing, digital printing machines do not need printing plates.

4. The use of recycled paper in digital printing can save landfill space. And reduce energy and water use in the paper making process. "China Printing Industry Annual Report"

Digital printing employs more eco-friendly processes. Such as waste reduction, and the use of recycled materials. More important it has minimal to no environmental impact. Digital printing reduces printing costs and reducing printing waste. While equipment operations have a positive impact on our environment.

In recent years, digital printing common use in different kinds of printing services. Such as cheap magazine printing, poster printing, booklet printing, and so on. Many people will say, digital printing is more green than traditional printing. Is that mean it can replace traditional printing?

Although digital printing as a green printing method has many advantages. But can digital printing replace traditional printing? The answer is not. Digital printing is currently more inclined to serve traditional printing rather than compete.

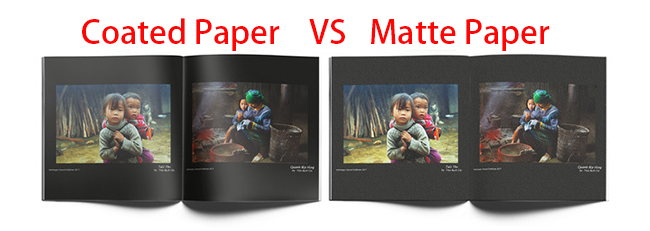

Although glossy paper and matte paper are common in China printing services. Many people do not know that glossy paper compare to matte paper,which is better? Next, let's compare glossy paper and matte paper through four aspects. They are appearance, texture, price, and printing pattern effects.

Coated paper also called glossy paper.Coated paper is light in weight and high in gloss and smoothness. Coated paper is often used to print a magazine or high-end book's covers and pictures. Or gift box printing. Matte paper has another name, matte-coated paper. From this name, we can know that the biggest difference between matte paper and coated paper is the surface gloss. Matte paper is not reflective on both sides in sunlight. While the surface of coated paper looks shiny.

glossy paper is a high-grade printing paper made of base paper coated with white paint. Common gram weights are 105g, 128g, and 157g coated paper. The production process of coated paper and matte paper is the same. But the coating formula is different. And the matte paper should be light pressure when overpressure.

How does Glossy paper compare to Matte paper?

The following is a detailed introduction:

1. Appearance

The manufacturing principle of glossy paper is to coat a layer of white paint on the base paper and then calendar it. Its biggest feature is the smoothness of the paper. Which is very smooth compared to ordinary paper. Besides, there are higher requirements for whiteness. According to such characteristics. When facing the light, the coated paper will have a more obvious reflective effect.

In a sense, matte powder paper is also a kind of glossy paper. Its official name is "matte coated paper" or "matte coated paper". Compared with coated paper, matte powder paper is a higher-grade paper. The difference between the two is no obvious reflection, although matte paper is not as bright as coated paper. But the fineness, matte paper is better.

2. Texture

As the glossy paper chosen by most customers. Although the whiteness is higher, it is still worse than the matte paper. Besides, the matte paper's hardness is also higher, and will not be easy to deform. But the price of matte paper is more expensive. From the perspective of cost, matte paper is generally used in the color field. While black and white paper generally uses glossy paper or double-adhesive paper. Such as story book printing.

3. Price

Since the properties of matte paper are better than glossy paper. The price of matte powder paper is also higher than that of glossy paper. After all, we often say that you get what you pay for.

4. Printing pattern effect

The patterns printed on the glossy paper are bright and vivid in color. And the image is realistic, with an effect like photos. But, the product printed on matte paper have more delicate patterns and low-key luxury. And can also improve the grade of the product. So matte paper is often used for the best hardcover book printing.

To summarize, the price, hardness, and printing pattern effect of matte paper are higher than glossy paper. But matte paper is not as bright as glossy paper.